Unparalleled Capabilities

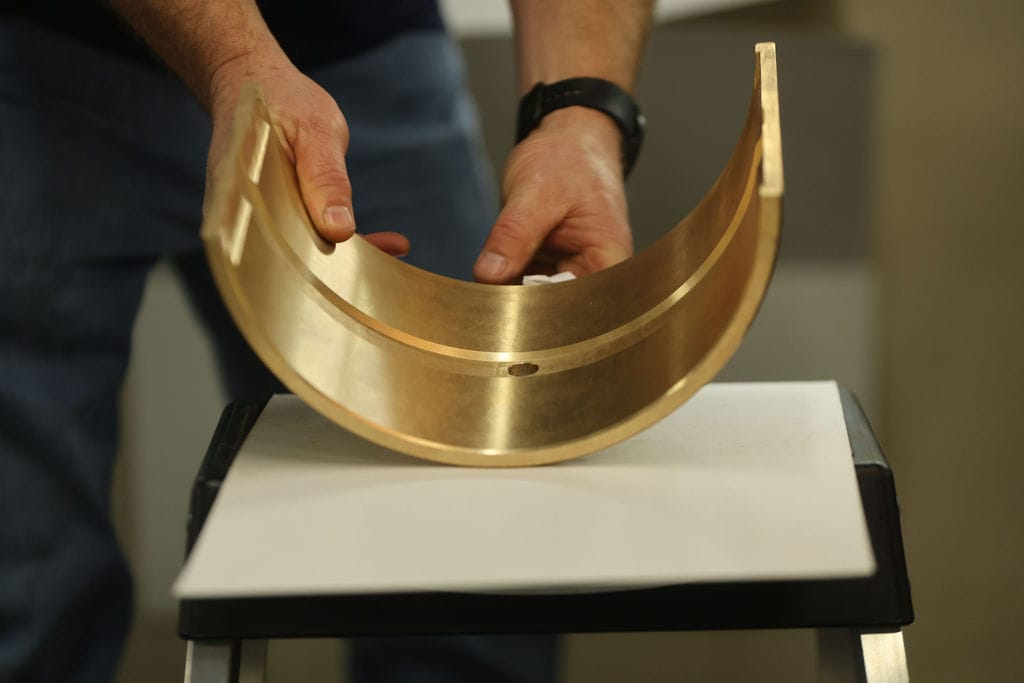

We provide industry-leading manufacturing capability, and our facility handles projects ranging from one-off components to large production runs of heavy wall bearings. Every step, from planning to tooling, machining, and inspection, takes place in-house, ensuring consistency and complete quality control. CNC machining centers, custom-built tooling, and decades of hands-on experience give us the ability to meet tight tolerances and unique requirements without compromise.

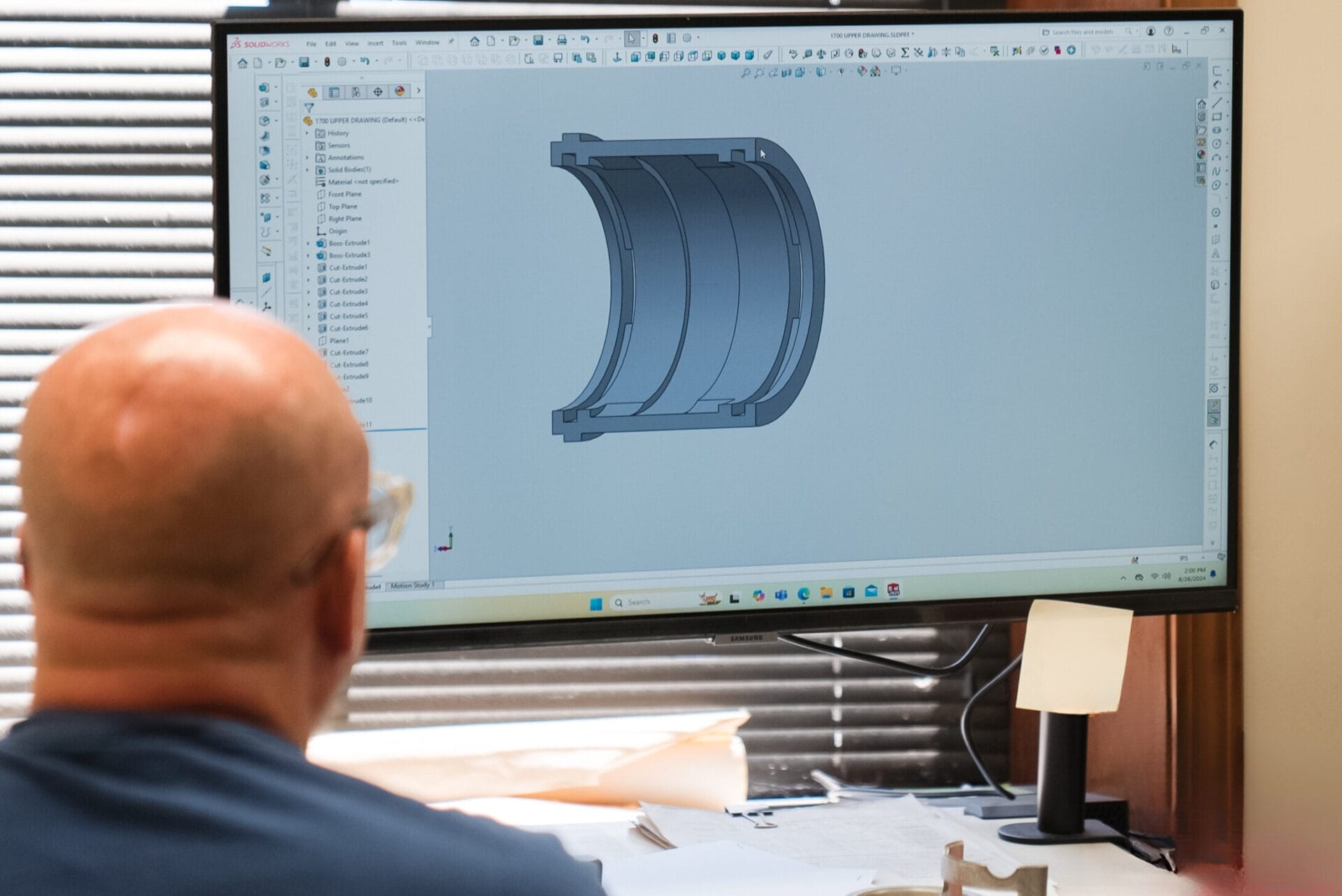

Engineering Support for Your Project

Every application is different, and having expert guidance can save time and reduce costly mistakes. Our in-house engineer is available to work directly with you, reviewing specifications and ensuring your heavy-duty bearings are designed for optimal performance. Whether you need help refining dimensions or selecting the right Babbitt alloy, our team provides practical solutions grounded in manufacturing know-how.

With the right materials, advanced manufacturing, and personalized engineering support, Quad Industries delivers heavy wall bearings that stand up to the toughest operating conditions.